A major breakthrough in liquid catalysis is transforming how essential products are made, making the chemical manufacturing process faster, safer and more sustainable than ever before.

Researchers from Monash University, the University of Sydney, and RMIT University have developed a liquid catalyst that could transform chemical production across a range of industries – from pharmaceuticals and sustainable products to advanced materials.

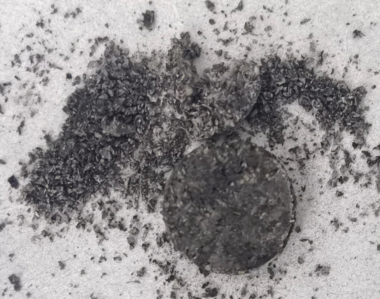

By dissolving palladium in liquid gallium the team, led by Associate Professor Md. Arifur Rahim from Monash University’s Department of Chemical and Biological Engineering, created a self-regenerating catalytic system with unprecedented efficiency.

The new catalyst demonstrated extraordinary performance in Suzuki-Miyaura cross-coupling reactions – a Nobel Prize-winning technique used to form carbon-carbon (C‒C) bonds – essential in pharmaceuticals, agrochemicals and materials science.

Their breakthrough, published in Science Advances, could revolutionise the production of essential products across industries, from life-saving pharmaceuticals and eco-friendly agrochemicals to advanced materials like plastics, polymers and electronic components.

“This new catalyst takes advantage of the unique fluid-like behavior of palladium atoms in a liquid gallium mixture, making it exceptionally effective at speeding up reactions – accelerating them up to 100,000 times faster than the best existing palladium catalysts,” Associate Professor Rahim said.

Explaining the process further, Senior co-author from RMIT Dr Andrew J. Christofferson said: "We found that palladium atoms would sit just below the liquid surface, activate the gallium atoms above, and the reaction would happen there. This is completely different from a solid-state catalyst."

Md. Hasan Al Banna, the paper’s first author, emphasised another key feature: "Another distinctive feature of this system is its operation as a true heterogeneous catalyst without the leaching of palladium ions, which can contaminate pharmaceutical products and present significant health risks."

The researchers hope their work will inspire further innovations in catalyst design, paving the way for greener, more efficient industrial processes worldwide.

Senior co-author Professor Kourosh Kalantar-Zadeh said: "This advancement is set to transform chemical manufacturing, delivering faster, safer and more sustainable production across industries, from pharmaceuticals to advanced materials."

DOI: https://www.science.org/doi/10.1126/sciadv.adt9037

-ENDS-

MEDIA ENQUIRIES:

Courtney Karayannis, Media and Communications Manager

Monash University

T: +61 408 508 454 or [email protected]

Monash University Media | +613 9903 4840 | [email protected]

Visit Monash Lens for expert insights and commentary