- Streamlining operations and reducing risk in asset integrity management –

TOKYO--BUSINESS WIRE--

Yokogawa Electric Corporation (TOKYO: 6841) announces that it has formalized a long-term agreement with Shell Global Solutions International B.V. (“Shell”) to integrate and further develop technologies for utilizing robots and drones in plant monitoring and maintenance. Under the agreement, Yokogawa will add an advanced machine vision tool called Operator Round by Exception (ORE), developed by Shell, into its own OpreX™ Robot Management Core. The enhanced software service will be made available by Yokogawa to customers in the energy, chemicals, and other industries.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20250617976629/en/

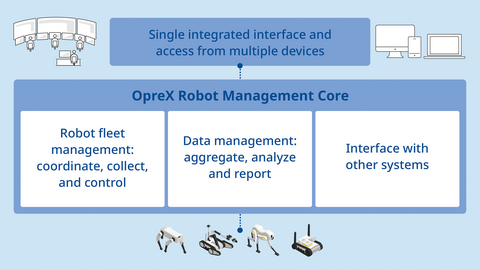

OpreX Robot Management Core

ORE is a digital solution that uses machine vision and AI analytics to enable robots to autonomously perform a number of tasks in the operator round process, such as reading gauges and checking for leaks and machinery issues. It is the result of a two-year collaborative effort within Shell, which combined machine vision strategy with deep capabilities in the field of integrity management, remote site inspection, and corrosion management.

OpreX Robot Management Core is a key product in Yokogawa’s robot solutions. The software helps customers maintain their facilities in a safer and more efficient manner by integrating the management of various types of robots that perform plant maintenance tasks conventionally carried out by humans. When connected to a plant’s control and safety systems, the data acquired can be used to issue instructions to robots, thus enabling the first step to be taken toward autonomous plant operations. The addition of Shell’s ORE technology will significantly increase the number of use cases available to customers through OpreX Robot Management Core.

Moving forward, Yokogawa robotics operations will deploy at two Shell facilities as a pilot into how robotics and drones can deliver value through efficiencies in plant monitoring and maintenance.

This collaboration is the first key milestone for Yokogawa working alongside Shell in the collaboration space at the Energy Transition Campus Amsterdam, which was created by Shell in 2022 to provide a platform for collaboration between companies, societal organisations, governments, and universities to work on tomorrow’s energy solutions. Shell and Yokogawa have also agreed to collaborate on an aligned R&D roadmap to further develop and enhance the machine vision technology, ensuring continuous innovation and improvement. This collaboration underscores both companies' commitment to providing cutting-edge solutions to the energy and industrial sectors.

Masaharu Maeda, Yokogawa Electric vice president, executive officer, and head of the company’s Solutions Business Division, stated, “We are very excited to be working with Shell on this key technology field that promises to address the workforce challenges facing plant owners by significantly improving the efficiency of rounds in the field, while also reducing the inherent risk to operators. We look forward to making it available to industrial facility owners globally in the near future and contributing to safer and more efficient workplaces.”

“Shell & Yokogawa have a proud history of developing together to enable advanced automation solutions for our sites. With this agreement, we are taking our relationship to the next level. Robotics solutions combined with AI provide the potential to create a step change in productivity and safety,” said Gerben de Jong, CIO for Shell Integrated Gas, Upstream and Projects & Technology.

For More Information

Robot and Drone Technology:

https://www.yokogawa.com/solutions/featured-topics/robot-and-drone-technology/

About Yokogawa

Yokogawa provides advanced solutions in the areas of measurement, control, and information to customers across a broad range of industries, including energy, chemicals, materials, pharmaceuticals, and food. Yokogawa addresses customer issues regarding the optimization of production, assets, and the supply chain with the effective application of digital technologies, enabling the transition to autonomous operations.

Founded in Tokyo in 1915, Yokogawa continues to work toward a sustainable society through its 17,000+ employees in a global network of 128 companies spanning 62 countries.

For more information, visit www.yokogawa.com

The names of corporations, organizations, products, services and logos herein are either registered trademarks or trademarks of Yokogawa Electric Corporation or their respective holders.

View source version on businesswire.com: https://www.businesswire.com/news/home/20250617976629/en/

Contact details:

Media enquiries

PR Department

Integrated Communications Center

Yokogawa Electric Corporation

[email protected]