- Australians generate around 20kg of e-waste per person every year

- Some of the components inside this everyday waste include critical minerals, which can be reused and recycled

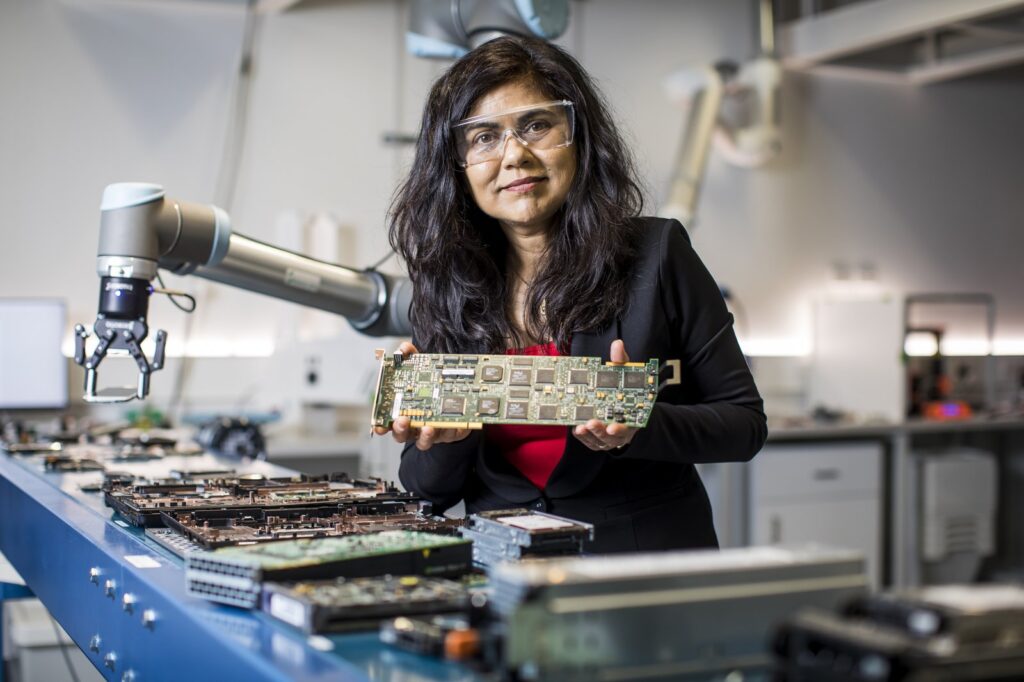

- At the National Press Club in Canberra today, Professor Veena Sahajwalla called on policymakers, industry and communities to embrace our waste.

As Donald Trump and Anthony Albanese announce a new, multi-billion-dollar critical minerals pact, UNSW Professor Veena Sahajwalla will tell the National Press Club in Canberra how onshore recycling technologies can recover these critical minerals from our waste stream — making the adoption of this cutting-edge technology a strategic, economic and environmental imperative.

At the National Press Club in Canberra today, UNSW Sydney’s Scientia Professor Veena Sahajwalla called on policymakers, industry and communities to embrace a new vision for Australia’s waste. Instead of relegating waste to landfills, incinerators or stockpiles, she argued it can drive innovation, support local industries, create jobs and deliver environmental and social benefits.

“True sustainability demands we harness this potential and transform waste into a resource stream for advanced manufacturing,” Prof. Sahajwalla said.

Australians generate around 20kg of e-waste per person every year, but many of the valuable minerals inside are never recovered. Some of the components inside this everyday waste include critical minerals, which can be reused and recycled, meaning there is both a strategic as well as an economic and environmental need to adopt this technology.

Using techniques Prof. Sahajwalla has designed, those waste resources can be reused and turned into new and valuable products.

E-waste is one aspect of a waste management crisis Prof. Sahajwalla’s work seeks to remedy.

In communities across Australia, her team’s pioneering MICROfactorieTM technologies are already showing what this future looks like. In Sydney’s south-west, discarded mattresses are being turned into green ceramic tiles, supporting local manufacturing jobs and helping councils reduce waste management costs. In Taree in regional NSW, reclaimed aluminium is being reformed into new aerosol cans. While in Sydney’s north, e-waste is being remanufactured into 3D printing filament.

“Using our waste resources as feedstock develops a circular economy where supply chains are linked up and local jobs are created, with significant environmental and social benefits,” she said.

Prof. Sahajwalla is Director of UNSW’s Sustainable Materials Research and Technology (SMaRT) Centre, which is internationally recognised for pioneering the concept of ‘MICROfactories’. The SMaRT Centre is home to MICROfactories technology, turning small, modular recycling systems that transform discarded products such as mattresses, glass, textiles, and electronic waste into valuable materials and products.

Her team’s work with councils and industry partners shows how this transformation is already taking shape:

Creating tiles from waste

In her address, Prof. Sahajwalla shared details of how the Liverpool City Council in Sydney’s south-west has turned a major waste problem into a circular economy success story. When the Council realised it was spending hundreds of thousands of dollars annually to dispose discarded mattresses it partnered with Prof. Sahajwalla’s SMaRT Centre to pilot a MICROfactorieTM to shred and re-manufacture the materials.

The Council bought an industrial shredder to process discarded mattresses into fluff. Then at the SMaRT Centre, Prof. Sahajwalla developed a technique which takes the fluff, mixes it with other waste products like broken glass and transforms them into tiles. What was once an expensive waste stream is now a resource: the council is producing durable, low-carbon ‘green ceramic’ tiles made from waste textiles and glass.

“It’s a tile and does everything you’d expect from a tile. It meets or exceeds Australian regulations, and you can use it anywhere you’d use a normal tile - floor tiles, kitchen back-splashes, council conference rooms,” Prof. Sahajwalla said.

Working with industry and communities

Prof. Sahajwalla’s Green Steel and Green Aluminium technologies are being used by industry partners. At JamesStrong Packaging in Taree, NSW, a new casting line uses reclaimed aluminium feedstock, produced through UNSW’s MICROfactorieTM technology.

“They produce 100 million aerosol cans every year, and soon a growing portion of that will come from reclaimed materials, making JamesStrong one of the first aluminium can producers in the world to do this,” Prof. Sahajwalla said.

She also outlined a vision in which MICROfactories could be established in cities, towns and regional communities across the country, each tailored to local waste streams and employment needs. In regional NSW, her team is working with the Aboriginal community in Wellington near Dubbo to use green ceramic tiles in sustainable housing projects, supported by the federal government’s Sustainable Communities and Waste Hub (SCaW).

Turning university research into real-world impact

Prof. Sahajwalla said Australia must do more to ensure university research translates into real-world impact. She called for governments to lead by example in adopting Australian-made sustainable technologies, and to reward companies that invest in local R&D.

“By and large, our professional incentives are not geared towards the long-hours it takes to actually build the machine that can make a world-saving idea a reality,” Prof. Sahajwalla said.

“We’re judged within the academy on the prestige of the journals in which our research appears, the citations that research generates, and the amount of grant funding we can draw in.”

“We have to buy what we’re inventing, set ambitious targets for the use of Australian innovations, because unless we create value then our very clever inventions aren’t worth a thing. We need to make sure government departments are using Australian tech, and that we reward companies that invest in Australian R&D with preferential consideration in government tenders.”

Contact details:

Copies of Veena’s speech are available under embargo, and she is available for interview before and after the speech. For further information, please contact:

Julia Holman - 0435 124 673, [email protected]

Yolande Hutchinson – 0420 845 023, [email protected]