Researchers have developed a breakthrough method to recover high-purity nickel, cobalt, manganese and lithium from spent lithium-ion batteries using a mild, sustainable solvent.

The process offers a safer and more environmentally friendly alternative to traditional high-temperature or chemical-intensive recycling methods.

Globally, around 500,000 tonnes of spent Lithium-ion batteries (LIBs) have already accumulated, and about 10 per cent of spent batteries are fully recycled in Australia.

The remainder often ends up in landfill, where toxic substances can leach into soil and groundwater, gradually entering the food chain and posing long-term health risks.

At the same time, spent LIBs are a valuable secondary resource, containing strategic metals such as lithium, cobalt, nickel, manganese, copper, aluminium and graphite.

Current recovery methods are often limited, relying on high temperatures or hazardous chemicals to extract only some elements.

The Monash team’s new method addresses these challenges by using a novel deep eutectic solvent (DES) combined with an integrated chemical and electrochemical leaching process.

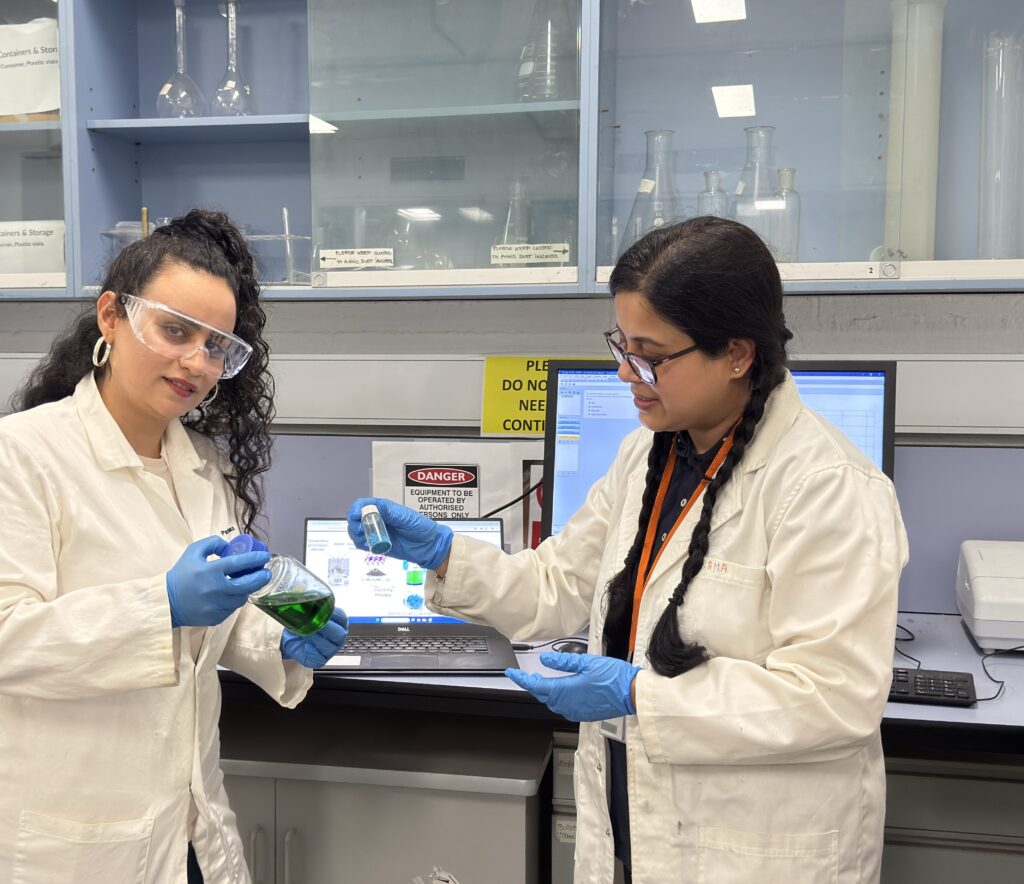

Dr Parama Chakraborty Banerjee, principal supervisor and project lead, from the Department of Chemical and Biological Engineering, said the approach achieves more than 95 per cent recovery of nickel, cobalt, manganese and lithium even from industrial-grade “black mass,” which contains mixed battery chemistries and common impurities like graphite, aluminum and copper.

“This is the first report of selective recovery of high-purity Ni, Co, Mn, and Li from spent battery waste using a mild solvent,” said Dr Banerjee.

“Our process not only provides a safer, greener alternative for recycling lithium-ion batteries but also opens pathways to recover valuable metals from other electronic wastes and mine tailings.”

Parisa Biniaz, PhD student and co-author, said the breakthrough is a major step closer to a circular economy for critical metals and reduces the environmental impact of battery disposal.

“Our integrated process allows high selectivity and recovery even from complex, mixed battery black mass. The research demonstrates a promising approach for industrial-scale recycling, recovering critical metals efficiently while minimising environmental harm,” Ms Biniaz said.

Read the research paper: https://doi.org/10.1016/j.susmat.2025.e01815

MEDIA ENQUIRIES

Courtney Karayannis, Media and Communications Manager

Monash University

P: +61 408 508 454

E: [email protected]

GENERAL MEDIA ENQUIRIES

Monash Media

P: +61 3 9903 4840

For more experts, news, opinion and analysis, visit Monash News.